Description

The LS Series offers a consistent stitching pitch and outstanding ability to sew sharp curves. This makes the machine ideal for sewing tubular articles.

Freight Charges Apply: After your purchase we will contact you with the final amount.

Please select Freight Charges Starting at: $299.00 upon check out to select the minimum charge.

Features:

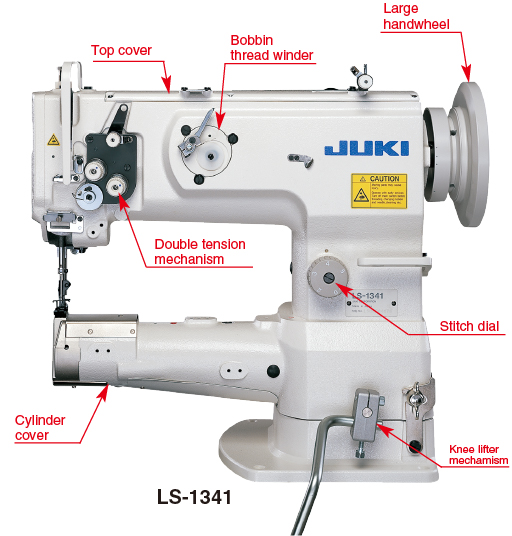

Sewing capabilities and feed performance that respond to a broad range of uses in the sewing of

heavy materials. With its larger needle bar stroke, larger lift of the presser foot, and newly adopted

double-tension mechanism, the machine sews beautifully with thick threads (low count thread) and at

higher thread tensions. This allows the machine to sew a broad range of heavy materials.

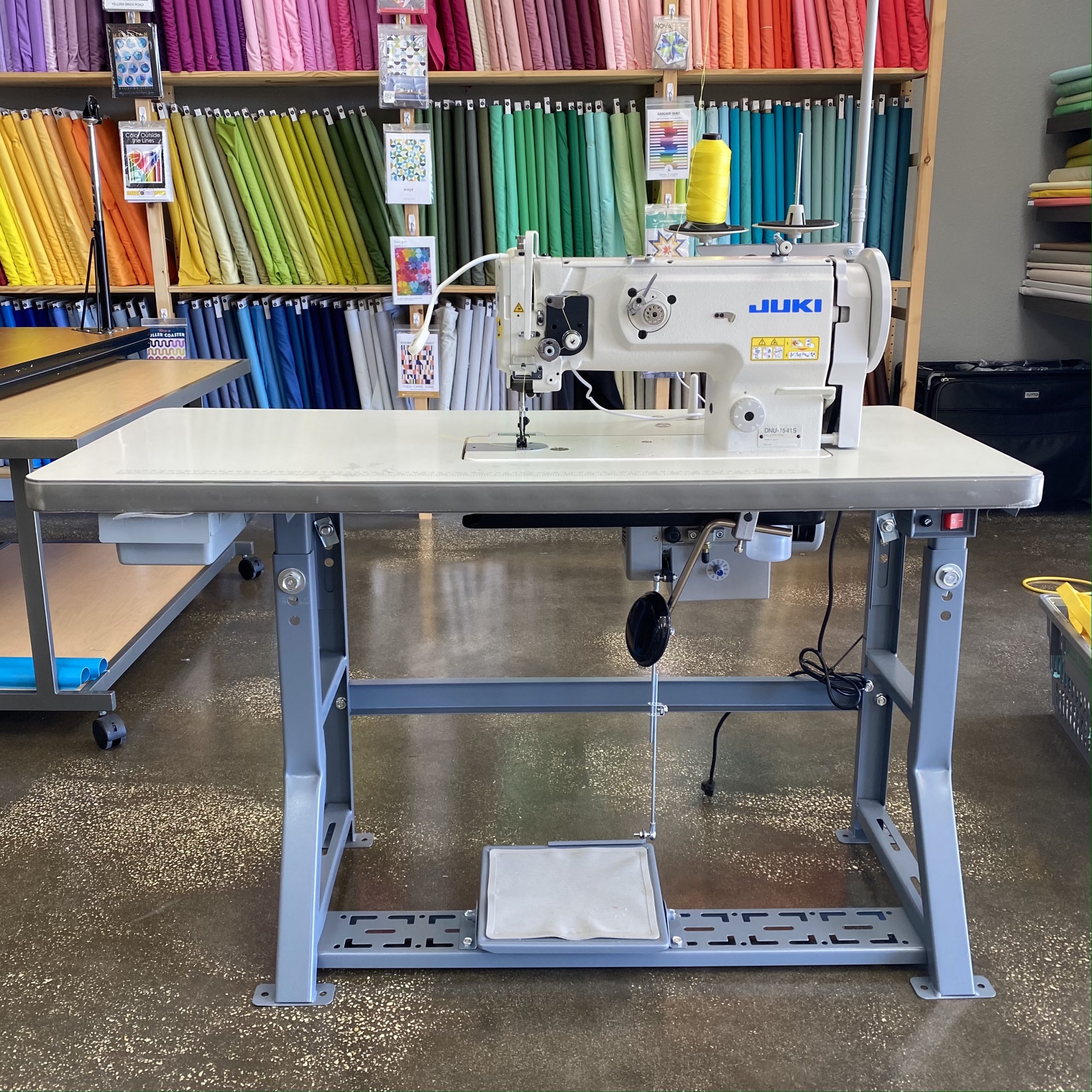

The Space Saver Stand options allows the machine bed to stick out from the left hand side of the table allowing an opening or free arm advantage. This table is 20 x 27.

Regular Table is 20×48

The newly developed mode of highly rigid rectangular feed guarantees outstanding feed performance.

In addition, the ratio between the alternating vertical movements of the walking foot and presser foot

remains unchanged even when the material thickness changes. With this feature, the machine sews

multi-layered parts of the material consistently and without stitch gathering.

The machine is equipped as standard with a mechanism to correct uneven material feed by

making-micro adjustments to the bottom-feed. Compared with the elliptical feed, the rectangular feed

helps reduce gathered stitches.

The slimmed-down throat plate easily adjusts to the sewing of small tubular articles with diameters as small as φ40mm. This enhances the machine’s ability to smoothly sew not only bags and shoes, but also small article such as wallets. The newly developed mode of highly rigid rectangular feed guarantees outstanding feed performance.

Reviews

There are no reviews yet.