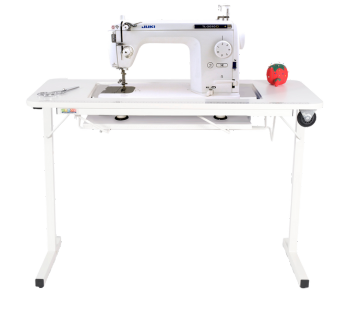

Juki DNU-1541S Industrial Walking Foot Single Stitch Machine With Servo Motor And Table

Juki DNU-1541S Industrial Walking Foot Single Stitch Machine With Servo Motor And Table

Juki

Suggested Accessories

Best For Creating

Select an icon to view image gallery.

Product Information

Specifications

Customers Also Shopped

Video Tutorials Hide Videos Show Videos

-

JUKI 1541S VS JUKI 1181 (IN DEPTH COMPARISON)

View VideoI hope you enjoy this video. It has been heavily requested for...

-

How to set up the Juki Industrial 1541S PT.1

View VideoIn this video we are going to show you how to set up up your i...

-

How to setup the Juki industrial 1541s PT.2

View VideoIn this video we will cover part two on how to set up the indu...

-

How To Thread And Wind Bobbin On Juki 1541S

View Video?️Juki 1541S ?️ https://jukijunkies.com/product/juki-dnu-1541s...

-

How To Oil The Juki 1541 Industrial (instructional)

View VideoUPDATE: We strongly recommend not removing the rubber caps on ...

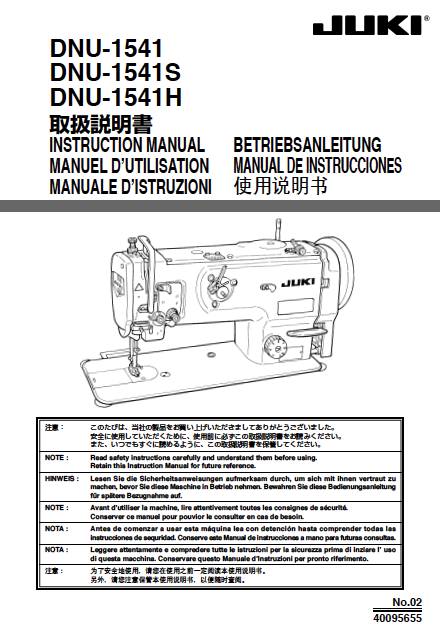

Manuals & Brochures

- Ideal for heavy bag makers, leather craftsmen, and marine or furniture upholstery

- Triple-feed walking foot industrial sewing machine

- Presser foot lift up to 0.63" – ideal for medium to heavy materials

- Speed Control: from 300 to 2,500 stitches per minute (SPM)

- Table size: 47" x 21"

- Equipped with servo motor, safety clutch, and needle guard

- Scroll down for a complete list of features and specifications

Standard Features:

- Walking Foot Mechanism: The walking foot system, helps feed thick fabrics evenly, especially when materials tend to slip or shift. The walking foot and presser foot move alternately by up to 6.5mm, and this movement ratio stays consistent even as the fabric thickness changes. This, combined with a new rectangular feed method, ensures smooth, even stitching on multi-layered fabrics without stitch gathering or fraying.

- Knee-lifter: Mechanism is built into the bed which facilitates raising the foot up to 16 mm.

- Heavy-Duty Construction: Built with industrial-grade materials, the 1541S is designed to withstand continuous operation in demanding environments. It's robust structure ensures long-lasting performance, making it suitable for both small businesses and large-scale factories.

- Large Sewing Area: The Juki 1541S features a large sewing area with a throat space of 477mm × 178mm, making it easier to handle large pieces of fabric. Its enhanced operability includes a clear view of the area around the needle, a conveniently placed bobbin thread winder on the front face of the machine arm, and a large hand wheel, all of which contribute to a smoother and more efficient sewing experience.

- Improved Needle Area Visibility for Enhanced Operability: The design of the area around the needle entry is optimized for easy observation, with the needle thread tension-release solenoid positioned on the rear face of the machine head. This placement, along with the one-touch reverse feed button, ensures that the operator has a clear view of the needle area, significantly improving the overall operability and ease of use.

- Lubrication: The machine comes with a lubricating mechanism that uses a centralized oil wick. This substantially reduces the time and trouble required for oiling the machine. It is recommended to oil the hook area.

- High-speed performance Increases Productivity: The machine delivers increased productivity at sewing speeds as high as 2,500 stitches per minute and as low as 300 RPM's with the Servo Motor while the optional digital motor can go as slow as 200 RPM's.

- Servo Motor: It comes with a high-torque, direct-drive motor, which provides smooth, consistent stitching without the need for a clutch motor. This makes it more energy-efficient and quieter compared to older models. This motor is a quieter and hardly makes noise. It is also draws less electrical power making it more efficient. The motor is the Family S Servo 550 W 3/4 HP.

- Optional Digital Motor for Needle Positioner: When using a needle positioner, a digital motor is used over a servo motor because it offers precise control, instant response, and advanced integration with the machine’s electronics, allowing for accurate needle positioning at specific points. Digital motors provide smooth, efficient power with real-time adjustments for varying tasks, ensuring the needle stops exactly where needed without jerky movements. They are more responsive and capable of fine-tuning the needle’s position.The motor is the brushless Juki J7R 650 W 3/4 HP.

- Safety Mechanism: This system allows the machine to stop operating to prevent further damage if a thread or fabric gets caught in the hook. If you are looking to not have this feature look at the Juki 1541 without the "S"

- Straight Stitch: The Juki 1541S is designed primarily for straight stitching, which makes it ideal for high-quality seam work on heavier materials.

- The Reverse Stitching Feature on the Juki 1541S is truly impressive. This machine offers seamless, precise reverse stitching that follows the exact line of the forward stitch, ensuring a clean, professional finish every time. It’s easy to switch directions, making it perfect for reinforcing seams or locking stitches.

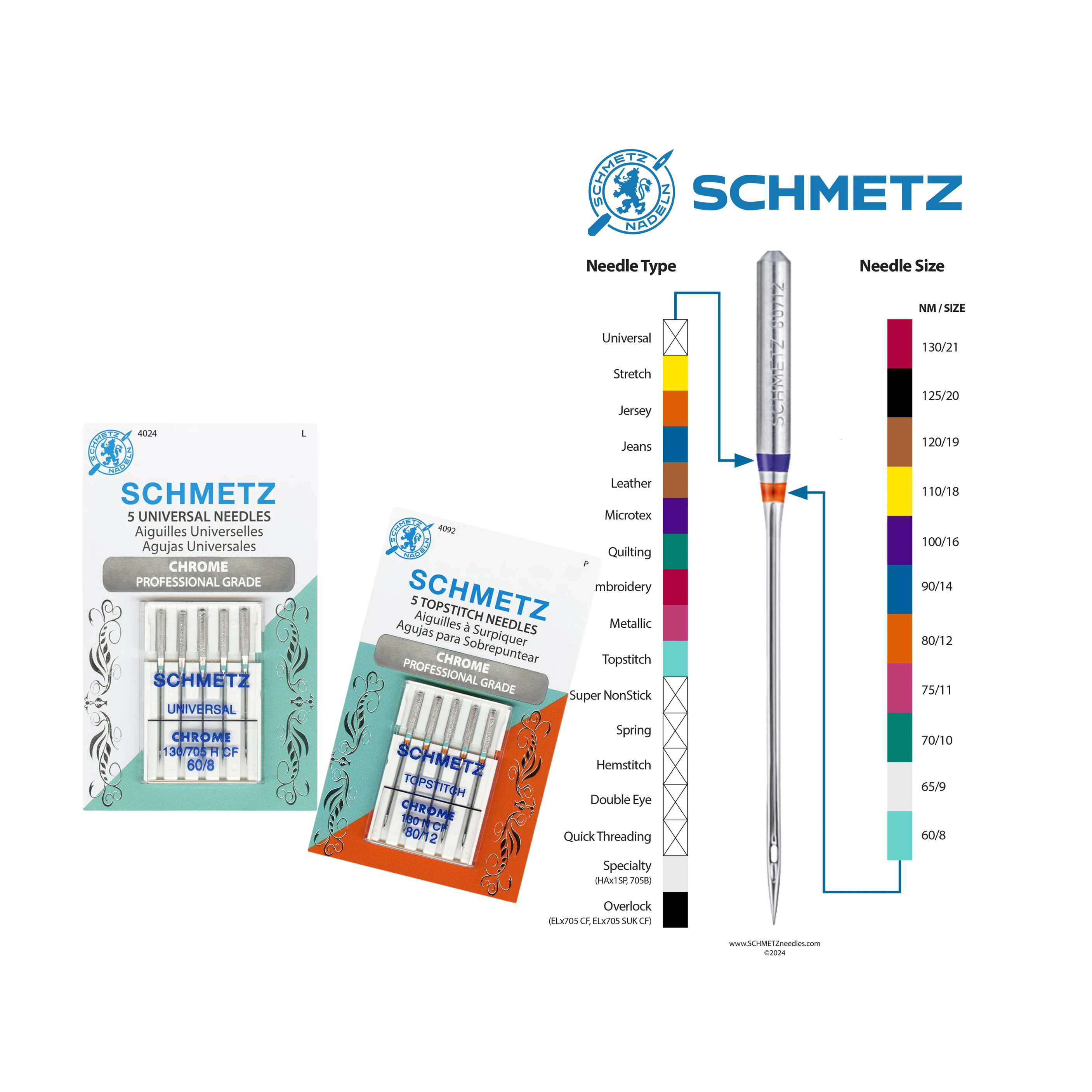

- Needle System: It uses a standard #135/17 needle system, making it easier to find replacements or upgrades depending on the material being sewn.

- Max Stitch Length: The stitch length can be adjusted up to 9mm, which is useful for different types of stitching, from basic seams to decorative or reinforcement stitches.

- Assembled with Servo Motor: refer to our installation video below on what to expect when you receive your Juki 1541S

Return Policy Disclaimer for Industrial Machines

Please note that due to the specialized nature of industrial machinery, all sales are final and these products are non-returnable once shipped. As these machines are tailored to specific needs, we are unable to accept returns after shipping has occurred.

We encourage you to carefully review product details, specifications, and compatibility before completing your purchase. Our team is happy to assist with any questions or concerns prior to ordering, ensuring the machine meets your needs.

By purchasing an industrial machine from our site, you acknowledge and agree to these terms.

What to Expect: Delivery, Setup, and Product Details

This product is sold as a complete unit. Upon delivery, it will arrive on a palette with the table fully assembled and the machine securely packaged in a box. For your convenience, we provide video installation help below to guide you through the process.

- Variations: Due to the nature of industrial sewing machines, table colors may vary and minor scratches on the table may occur during shipping. This is normal and to be expected with industrial machinery deliveries.

- Needle Positioner Orders: If you’ve chosen to add a needle positioner to your machine, please note that the box will be opened by our technicians to install the needle positioner before shipping. This ensures proper installation and quality control, but rest assured, all components will be carefully re-packed for safe delivery.

- Manual: The machine does not come with a manual. Please scroll down to view or print manual.

- Open the Drawer: Open the drawer in the table to find accessories.

Why Choose the Juki DNU-1541S?

If you're looking for a machine built for power, precision, and professional-grade performance, the Juki DNU-1541S is a top contender. Designed for high-demand sewing environments, this machine delivers exceptional feeding stability and strength for even the toughest materials. Its true walking foot system sets it apart, making it ideal for upholstery work, leather, canvas, and other heavy-duty applications.

What’s the Difference Between the Juki DNU-1541S and the Juki DNU-1181N?

Understanding how these two models compare is key to choosing the right machine for your specific needs. While the two models share some similarities in build quality and design elements, their feeding mechanisms set them apart, affecting the type of materials they suit and how reliably they feed those materials.

Juki DNU-1541S — True Walking Foot (Compound Feed / Triple Feed System)

- Feed System: Features a compound feed, also known as a triple feed system, where the needle feed, inner presser foot feed, and bottom feed (feed dogs) all move in synchronized motion.

- Action: With this system, fabric is firmly gripped from both the top and bottom and pulled evenly through the machine. This significantly reduces slippage, shifting, or skipped stitches, especially when working on layered or heavy materials.

- Ideal For: Upholstery, leather goods, tarps, car seats, canvas bags, denim layers — anything that demands strength and consistency.

- Benefits: Delivers excellent stitch quality even over thick seams and layered fabrics. It’s built for long hours, tough materials, and jobs where failure is not an option.

Juki DNU-1181N — Top & Bottom Feed (Scuff Feed System)

- Feed System: Uses a top and bottom feed system, often referred to as a "scuff feed" — where the inner and outer presser feet alternate to move the fabric while the feed dogs push from below.

- Action: While this system is fine for medium-weight materials, it lacks the added grip of a needle feed, which can lead to shifting or uneven stitches on tougher projects.

- Ideal For: Light to medium-weight materials such as light canvas, vinyl, and synthetics.

- Limitations: Not recommended for dense or multilayer materials. It may struggle on heavy seams and isn't built for continuous high-torque use.

Quick Comparison:

Feature |

Juki 1541 (Triple Feed) |

Juki DNU-1181N (Scuff Feed) |

| Feed Type | Compound / Triple Feed | Top & Bottom Feed |

| Needle Feed | Yes | No |

| Heavy Material Handling | Excellent | Moderate |

| Stitch Consistency | Superior | Can Vary |

| Fabric Shifting | Minimized | Possible |

| Ideal For | Upholstery, Leather, Tarps | Vinyl, Light Canvas, Synthetics |

Bottom Line:

If you're tackling professional upholstery, bag making, or other heavy-duty applications, the Juki DNU-1541S is the powerhouse you need. It’s built to handle stress, volume, and weight with ease. While the Juki DNU-1181N is a great choice for lighter work and general use, it simply can’t match the stability, strength, and stitch integrity of the Juki DNU-1541S when it comes to rugged, industrial-grade sewing.

Made in Japan

2,500 Stitches Per Min.

Sewing Speed Max9mm

Max. Stitch Length16mm

Lift of Presser Foot by Knee9mm

Lift of Presser Foot by Hand135 x 17

Needle System36mm

Needle Bar StrokeSize 18 - 23

Needle RangeBonded Nylon

Thread Type69-92

Thread Range10" x 7" H

Needle to Inside of Head18.7" W x 7" H

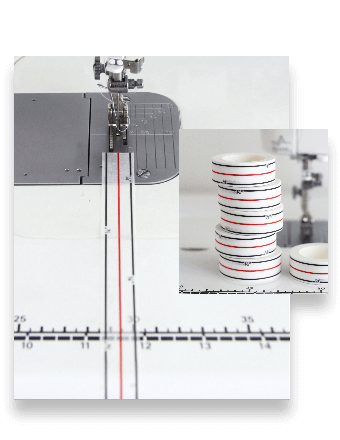

Throat Space20" x 47"

Table DimensionsJuki New Defrix Oil No. 2

Lubrication Oil80 lbs

Weight of Machine Industrial Threads

Industrial Threads

Discover the world of industrial threads and the strength they offer. We provide a range of industrial threads designed to support any project under your sewing machine.

Shop All Machine Care

Machine Care

A clean machine is a happy machine. Make sure you have the right tools at home to maintain your machine so you can keep sewing instead of guessing what’s wrong.

Shop All Industrial Accessories

Industrial Accessories

Need more bobbins? Or maybe you're looking for a backup bobbin case? Explore essential accessories for your Juki industrial machine, including presser feet, attachments, and more.

Shop AllYou May Also Like

1 Review Hide Reviews Show Reviews

-

Review by Ardena

This machine is so beautiful! I’ve had mine for a little over 6 months now and am in love. It sews beautifully, the stitches are always even and consistent. Setup was a breeze with the videos on Juki Junkies YouTube Chanel.