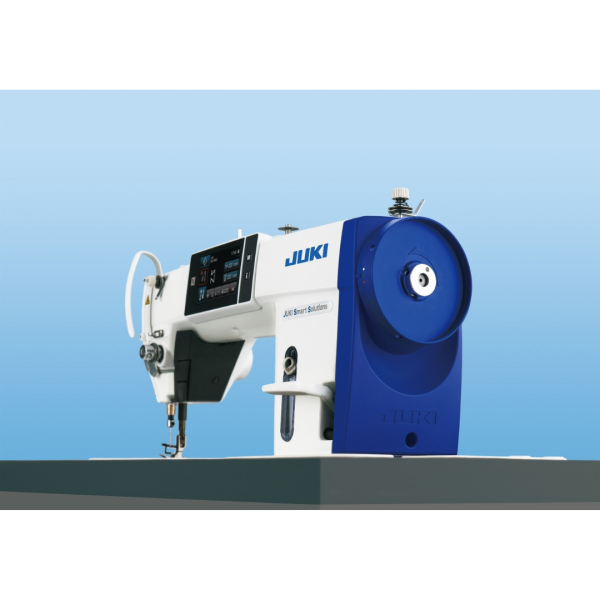

Description

1-Needle, Unison Feed, Lockstitch Machine With Vertical-axis Large Hook

The maximum stitch length is 10mm. The complete rectangular feed locus enables accurate feed of extra heavy materials while preventing stitch gathering. With its sufficient needle bar stroke of 38mm and long 190R needle, the compound feed machine supports the sewing of extra heavy materials. The walking foot machine comes with an extra-large steel handwheel with a diameter as large as φ175.

A new feed mechanism with a rectangular feeding motion prevents stitch gathering

The new mechanism with a rectangular feeding motion promises consistent feed of materials of all thickness without stitch gathering.

The lower orbit of the feed dog prevents the material from flopping and reduces operating noise and vibration.

The alternating vertical movement mechanism prevents irregular stitches

The machine has adopted a new mechanism that does not change the ratio of alternate vertical movement of the walking foot and presser foot even when the material thickness changes.

Even when a heavy-weight material is used, the presser foot lift does not decrease. This means that the presser foot comes into contact with the material at exactly the same time that it does when sewing lighter-weight sections of the material. As a result, the walking foot retains the material with a consistent pressure to prevent irregular stitches.

The amount of the alternating vertical movement of the walking foot and presser foot can be adjusted up to the maximum of 6.5mm according to the height of multilayered portions of the material.

Consistent seam quality

With the adoption of a new rectangular feed mechanism, an alternating vertical movement mechanism, and a unison feed mechanism, the machine can feed heavy materials powerfully and smoothly. Well tensed seams are consistently produced without pitch errors.

With its maximum stitch length of 9mm, the machine can be applied to a broader range of uses.

Higher lift of the presser foot

The high, 16mm foot lift enables easy material handling.

The machine comes with a dual-tension mechanism

The 1-needle type machine has adopted a dual-tension mechanism, with which the machine can support high-tension sewing with thick thread. This means that the machine produces seams of excellent quality on a broader range of materials, extending from light- to heavy-weight.

The highly efficient vertical-axis double-capacity hook is equipped as standard

With the adoption of this vertical-axis double-capacity hook, the frequency of bobbin thread changing is reduced, promising sewing work of increased efficiency.

Improved operability

The stitch length can be easily selected by the stitch dial.

The machine is provided with many improved features that offer enhanced operability such as an easy-to-observe area around the needle, placement of the bobbin winder on the front face of the machine arm, and a large handwheel (φ160).

A knee-lifter mechanism is built in the bed. This reduces the pressure required to operate the knee-lifter and facilitates setup. (Machines equipped with automatic thread trimmer are excluded.)

The machine is a full-open-type top design that makes it possible to fully open the top of the machine arm. Thanks to this design, adjusting works can be done without tilting the machine head.

The machine is equipped as standard with a safety clutch for preventing hook breakage. Reset work can be done simply by pressing a button.

Reviews

There are no reviews yet.