Description

The Juki LK1900S

JUKI Simple Series sewing machine LK-1900S has been designed to have simplified and narrowed down capabilities that are essentially required to produce JUKI’s established seam quality. In addition, it supports the operator with the voice guidance system to improve work efficiency.

Juki’s quality is achieved by simple functions:

Higher Productivity

This sewing machine shortens the total cycle time with its improved capabilities such as the maximum sewing speed of 3,200 sti/min, quick acceleration at the beginning of sewing and quick deceleration at the end of sewing, increased thread trimming speed and work clamp foot lifting speed.

This sewing machine quickly carries out sewing of various kinds of sewing patterns

The sewing machine is provided as standard with 51 sewing patterns with different stitch directions and number of stitches, such as large bartacking, small bartacking, straight line tacking. The operator can select the best-suited sewing pattern according to the given process. (In some cases, the work clamp foot and other parts may be required to be changed.

The sewing machine provides the sewing area of 30mm(length) × 40mm(width).

With its large sewing area, this sewing machine can be fully utilized for sewing various kinds of sewing patterns such as lengthwise bartacking. In addition, the sewing machine has such a large memory capacity to store many different scale ratios, numbers of stitches and numbers of sewing patterns, thereby ensuring improved flexibility.

Feed control systems

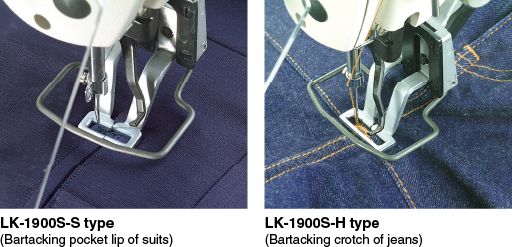

●The LK-1900S comes in two different types; i.e., S type (Standard) and H type (for Heavy-weight materials). Customers may select one of these types according to their applications.

●The sewing machine has adopted a sufficient-in-power 550-W motor. With this motor, the sewing machine allows the needle to penetrate into heavy-weight materials smoothly.

●Bartacking data contained in a pattern number can be changed with ease by means of the pattern enlargement / reduction function. This operation can be done by entering the scale ratio through the operation panel.

●Standard sewing patterns can be registered to the pattern keys P1 to P50. In addition, the registered patterns P1 through P25 can be called up by a touch of the corresponding pattern key. It is advised to register 25 sewing patterns you use frequently to the pattern keys P1 to P 25 in order to improve workability.

●The operation panel is provided as standard with a USB port. This means that the sewing machine data management and software updating can be carried out with ease by means of the USB port.

This sewing machine is provided as standard with the voice-guidance system with clock function. This voice guidance can be used for the purpose of production support such as giving the operator information about the number of pieces produced, work progress management and the operation rate of sewing machine, though the initial setting is required.

——–Table included:

Included:

FOR MORE DETAILED INFORMATION please click on this LINK

Recommended for: Apparel,

Returns: Due to the delivery and size of the machine returns are not accepted.

Variations: Due to the nature of industrial sewing machines table colors may vary.

Disclaimer: Industrial machines are tough, but due to their weight there may be some minor scratches on the head or the table during shipping. This is normal when shipping industrial sewing machines.

Delivery: Juki LK1900S Curbside delivery by freight. The table and machine come assembled on a palette ready to sew.

Freight Charges Apply: After your purchase we will contact you with the amount. Please select PENDING FREIGHT CHARGES upon check out.

For additional information we recommend you look at the brochure below this section and the features tab.

Reviews

There are no reviews yet.